Latest Application Technologies

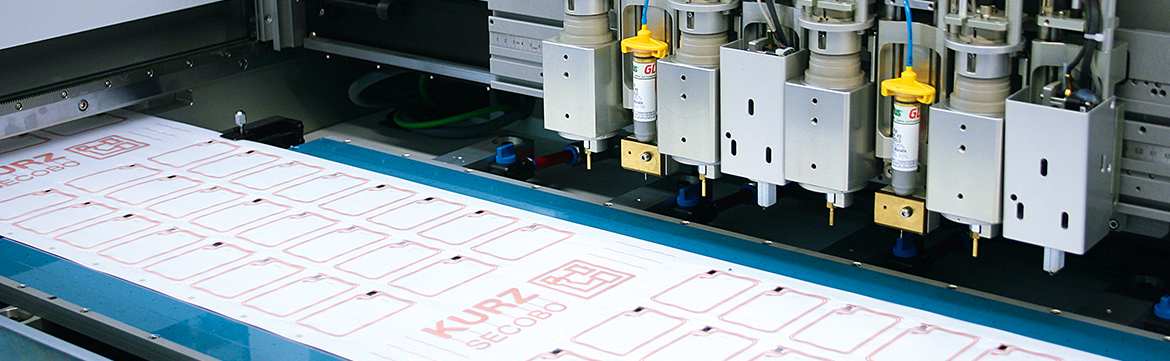

The MELZER M4 system is ideal for the production of RFID inlays for plastic cards, e-passport components and antennae for dual interface cards. Coils and/or complete inlays can be made quickly and reliably by digital manufacturing on one or several M4 systems – automatically reel-to-reel or reel-to-sheet.

In addition to the familiar antenna laying process, the M4 also offers inlay production from pre-fabricated antenna reel material.

For MRTDs and e-NIDs preferably, plated antennae on PC substrate are used. In parallel to the assembly, further compensation foils can be precisely punched and applied. After the thermo-compression soldering process, patented by MELZER, the inlays are tested, if applicable marked, cut to format (e.g. 3×8) and stacked.

The digital technology of MELZER’s M4 system stands for precision, maximum productivity and reduced tooling and set-up costs. Prototypes and mass products alike can be produced economically in constantly high quality.

A good choice for smaller quantities is one M4 system, which can be equipped with up to 8 different modules. Higher output figures can be achieved by combining several M4 systems with maximum equipment of the Z-axis.

The modular design offers the highest flexibility, which in combination with MELZER standard modules, means an infinite number of products can be manufactured.

The M4 system is suited for manual production as well as for the fully automated industrial process.

The production capacity of the M4 systems can be adapted to the requirements and increased when necessary. The production steps in question can either be made on one M4 system or several M4 systems may be connected to a high-speed production line.

When the last production step has been carried out, i.e. after testing and marking of the inlays, the continuous material is sheeted and stacked. Cover or compensation foils can be added and fixed precisely in register.

Quick Links