Basics of Modified Atmosphere Packaging

|

|

MAP Packaging & Packmaster Web Direction

Modified Atmosphere Packaging (MAP) is well established in the food industry and continues to gain in importance. MAP means, that the natural ambient air in the package is replaced by a gas or gas mixture, often nitrogen and carbon dioxide. This packaging under a protective atmosphere preserves the quality of fresh produce over a longer period of time, extends shelf life, and gives food producers access to a geographically larger market for perishable products. This is suitable for meat and sausage products, fish, dairy products, bread, fruit and vegetables, and convenience products.

Modified Atmospheres are not limited to the packaging process. They can also feature as part of the production process, for example, in the storage and transport of fruit and vegetables in halls or containers.

The standards required by Modified Atmosphere Packaging are comparatively high and must be controlled and monitored to ensure safety. Therefore, food manufacturers rely on modern MAP gas technology and various levels of quality assurance for maximum process safety.

Benefits of Modified Atmospheres Packaging

Longer shelf life / higher quality

Food packaged under a protective atmosphere spoils at a much slower rate. Combined with continuous cooling, Modified Atmosphere Packaging can significantly extend the freshness and shelf life. This effect varies depending on the product type. However, a doubling of the shelf life is usually possible. In general, MAP products keep a high quality over a longer period of time and arrive at the consumer in the best condition.

Less waste

Longer durability is often associated with fewer problems during long distance shipment – and a longer shelf-life. As a result, waste disposal due to spoiled food can often be reduced.

More sales opportunities

Because of the longer shelf-life, Modified Atmosphere Packaging typically opens up new geographic markets to manufacturers. Particularly with perishable goods, longer shipment distances can be achieved and a global market become a reality.

Fewer preservatives

As packaging under a protective atmosphere extends the shelf-life of food, the use of preservatives can be reduced or even completely eliminated in many cases. Consumers get products that do not contain artificial additives.

Appealing package design

Next to functional aspects, the design of the packaging plays a significant role in winning new customers. The look and feel, in addition to the quality impression, influence the purchasing behavior. Modified Atmosphere Packaging is very well suited for the most appealing package design and presentation of the food product.

Typical gases for Modified Atmosphere Packaging

Carbon dioxide (CO2) and Nitrogen (N2) are the main protective gases used in food packaging. Carbon monoxide (CO) and Argon (Ar) are also common in some countries, for example, in the US. And Oxygen (O2) is also used in some cases.

Foods suited to Modified Atmosphere Packaging

Modified Atmosphere Packaging is suitable for a wide range of food products. While traditionally mainly dairy products (meat products and bread were packaged under a protective atmosphere) now MAP is increasingly used for other foods, such as fish, coffee, fruit and vegetables. In addition, Modified Atmosphere Packaging is driven by the growing popularity of ready-made meals and convenience products, such as: Meat and sausage products, Fish and Seafood products, Dairy products, Bread and Cake, Fruit and Vegetables, Pasta and ready-made meals, Snacks and Nuts

Packmaster Web Direction: MAP solution for converting companies.

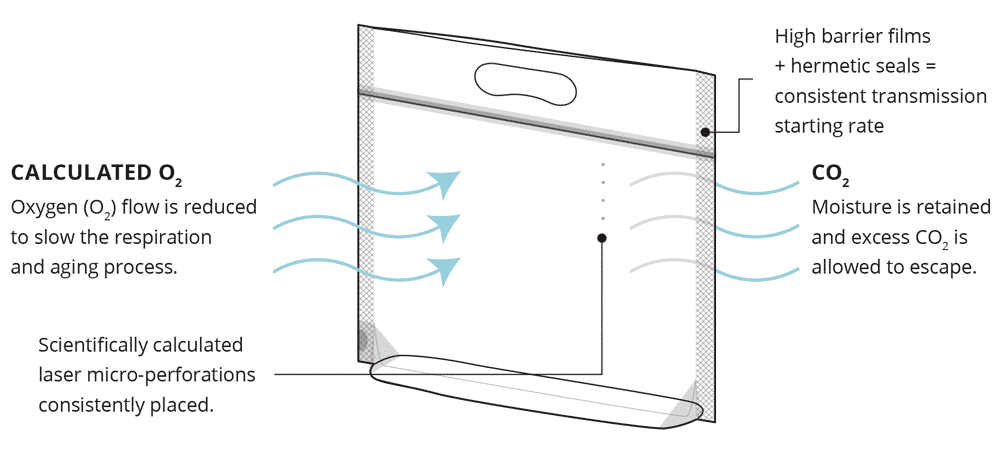

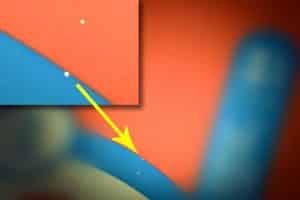

MAP Technology is customized specifically for your product and operation, taking into consideration respiration rate, package weight, volume and anticipated distribution temperatures. MAP technologies use precise laser micro-perforations thanks to Packmaster Web Direction to provide an effective MAP package. The laser micro-perforations are more than 5 times smaller than standard mechanical micro-perforation. These smaller perforations allow for a more controlled exchange of gasses for improved MAP packaging effectiveness.

Testing shows that over an 18-day period, produce packed with MAP packaging guarantee a moisture loss rate of less than 1%. This moisture retention increases shelf-life, maintains weight, color and texture increasing visual appeal and protects against harmful microorganisms.

|

|

| STANDARD HOT NEEDLE PACKAGING Moisture Loss = 43.7% |

MODIFIED ATMOSPHERE PACKAGING by Packmaster WD Moisture Loss = 0.1% |

|

|