Pharmaceutical products demand intensive product validation processes before they can be released to the market. Such validation even includes the production equipment and production processes. OLBRICH is the key supplier of GMP Coating Lines to the Medical and Pharmaceutical Industry and addressed the market need for a reliable, lab-scale coating line for pre-production validation of products and processes. The new line features proven OLBRICH technology in lab scale and will mainly serve to manufacture pharmaceutical plasters and other medical products and is designed according to GMP guidelines. The Cleanroom Class is “D”.

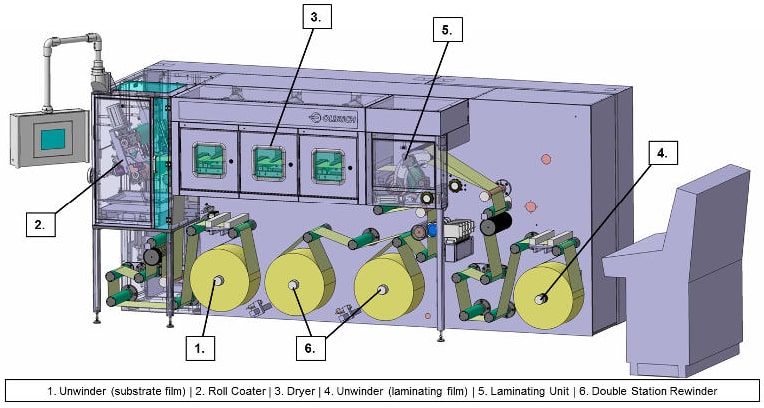

The line mainly consists of: Unwinders and Winders: roll weight max. 60 kgs, 500 mm roll diameter, with automatic edge guiding. Roll Coater (E Ex performance for solvent based coatings) for direct coating. Hard-chrome plated coating rolls with T.I.R. of 0,003 mm for precise coating weights. Further coating systems include slot-die coating and comma bar coating heads. Mass supply: for solvent based medium, with GMP compliant pump system. Dryer: The dryer designed as nozzle drier serves to dry single-side coated materials. It consists of 3 zones. Temperature accuracy +/- 1,5° C across web width. For the operation of the line with solvent-based media, the dryer is designed according to DIN EN 1539. Slitter: with five blades for edge cutting and for separation into up to four individual material webs.

Drive System: Siemens, Servo motors and Sinamics S120 converters Operator Interface: Siemens TP1500 15” Touch Main Panel. The PC based scada system is based on WinCC. It will be prepared according to GAMP 5 and conforms to the FDA guideline 21 CFR Part 11. The machine comes with the GMP compliant documentation for safe validation. With this new line, OLBRICH successfully closes the gap between small-size table top coaters and small production lines – pre-validation will be enabled to the benefit of our customers and for accelerated time to market circles.