Move Your Business and Profits Forward

North American Supplier for Premier European Equipment

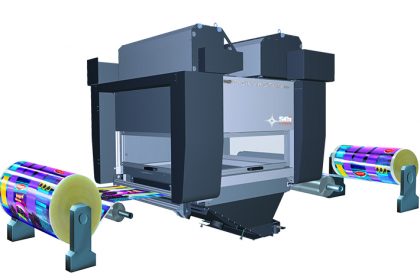

Increase revenue and profits, improve efficiency, outperform your competition, and grow your business with premier European equipment from Matik, Inc. Advanced technologies and equipment from SEI Laser, OLBRICH, Melzer, Kelva, SENSOTEC and others have been proven worldwide to help companies:

- Work smarter

- Offer unique capabilities

- Create customized products in small and large quantities

- Open new market niches

- Reduce labor and waste

- Achieve better results

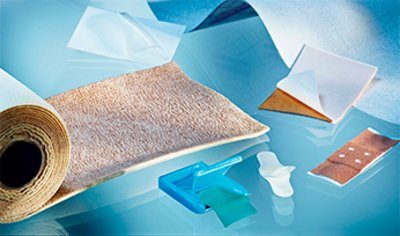

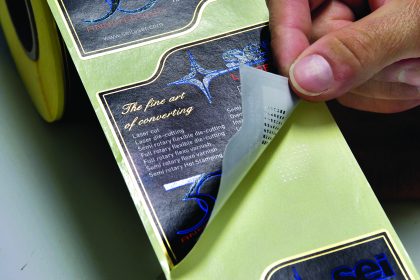

Matik, Inc. is the leading North American supplier for premier European equipment used for acrylic/LED backlighting, commercial printing, converting, folding carton, labels, RFID and security tags, transdermal drug delivery and more. Our factory-trained technicians provide preventive maintenance for our equipment, and our expert staff performs quality inspections, diagnosis, repairs and aftercare.

We sell and service a variety of state-of-the-art equipment: